No one liked it.

Will it brew 2019?

Another June, another set of weird ingredients. This year we weren’t as prepared as we could have been. Our holiday was booked around Home brew Sunday because we really wanted to take part but, stupidly, we left it rather late to pick up ingredients to take along.

Thus we found ourselves at a farm shop between Sussex and Manchester picking up random items and asking “Will it brew?”. We came home with liquorice, stuffing and pork scratchings with the intention of inflicting one on some expectant sap the following day.

Actually, what happened was that we liked the look of the expensive liquorice, the posh stuffing and the fancy pork scratchings so popped into Morrisons on the way to the event. There we picked up some Morrisons own brand sage and onion stuffing instead. Practically it would have been difficult for anyone to find the same, fancy, ingredients if they didn’t have enough (unlikely).

On the day people brought along quite an eclectic set of items, including a surprising number of Oriental options such as wasabi and miso. James took down a list of who brought what which I’ll point to once he’s published it.

Our stuffing finished up in the hands of expert sour brewer Keith Sowerby. Steve got kidney beans, which he was less than happy about as they “have no taste!”.

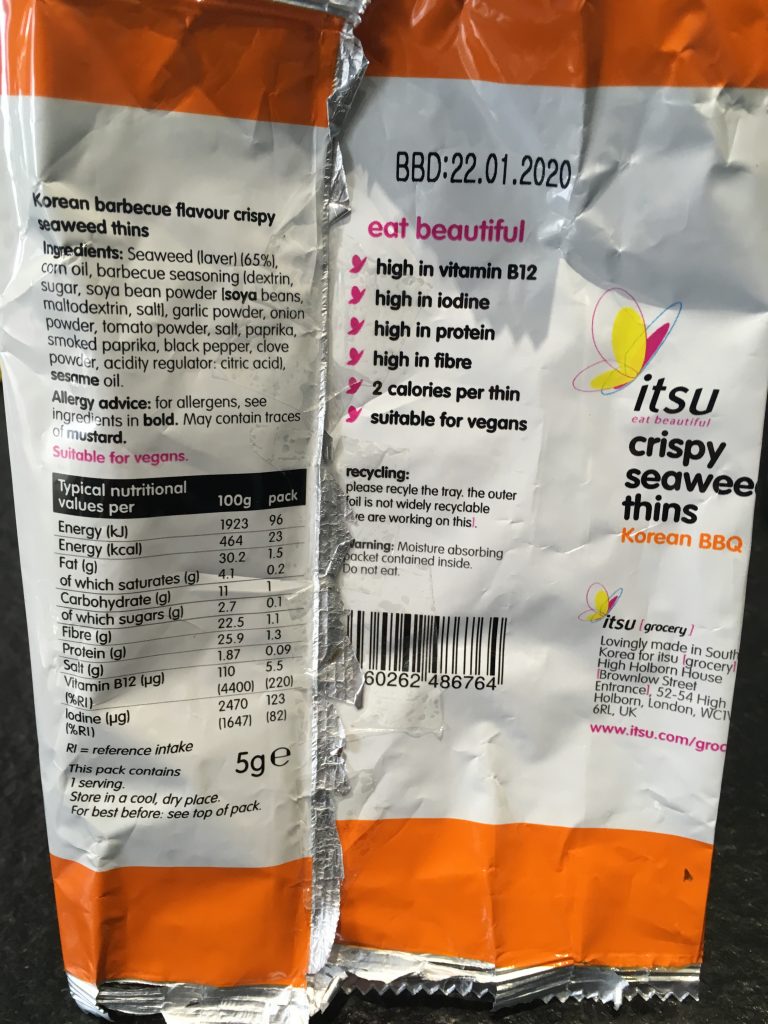

Beardy Dan (mead maker Snoring Bear) sent in absentia a bag of Korean BBQ flavoured crispy seaweed thins, which are now our ingredient we have to brew with. There’s so much wrong with this. BBQ? Seaweed? The massive bags contain no more than 45g in total. Of that about 20g is fat, not a brewer’s friend.

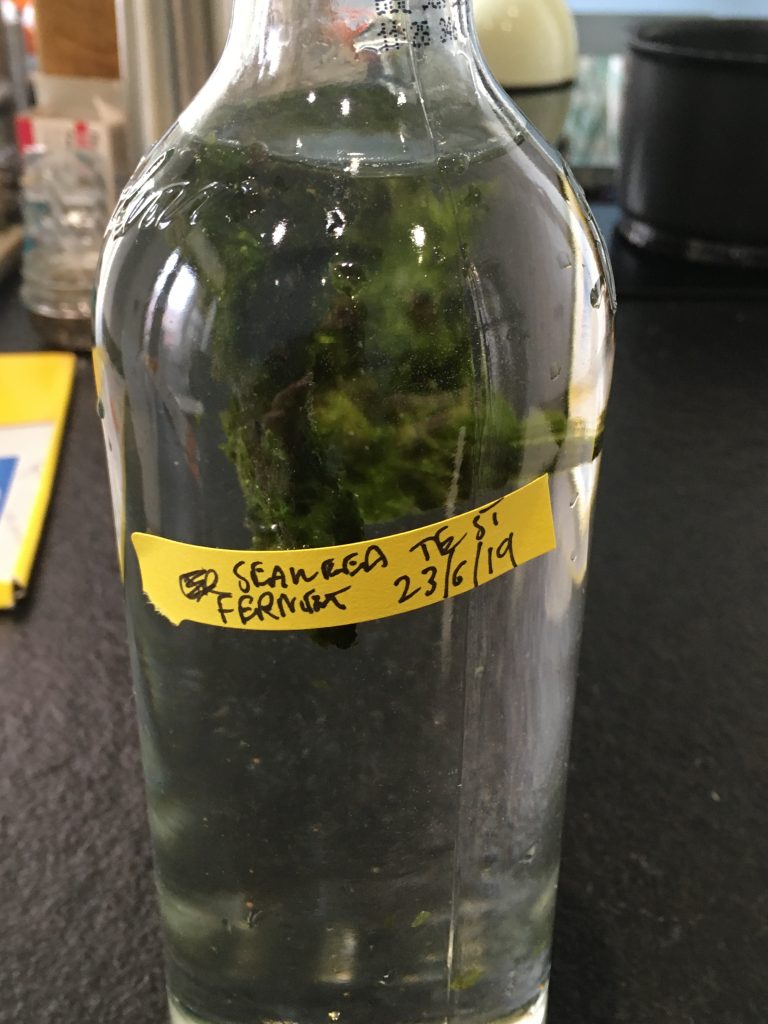

Yes, it’s translucent.

Left for a week to see what happens to the BBQ flavour

Not processed, oh no.

Last week we tasted one each. Pen quite liked them, Mike not so much. They live up to their name. Definitely Korean BBQ flavoured. Definitely Seaweed and very, very thin. Each weighs less than 1g, roughtly 0.3g.

This weekend we decided to see what happened when we immersed them in water. One thin each in a ‘mash’ (thermos flask) at about 67C for an hour, boiled for 15 minutes and left in room temperature water for a week.

The boiled one smelled of seaweed whilst boiling but the intensity dropped after 10 mins. There was plenty of flavour in the remaining water though.

The mash seemed less successful with less flavour in the liquid. We’ll have to wait to seee what happens to the one in the bottle of 20C water.

As research we contacted a couple of breweries known to make seaweed beer. One, Portsmouth Brewery from Maine, replied and offered some useful advice and information. Thanks Maxine. She gave us an idea of quantity to use (26g/L towards the end of the boil) and a description of the flavours in the final beer. She advised to keep the hops bittering low too.

What are we going to brew? Probably our basic Magnum Blonde with a higher salt contribution, mininal bitterness and a typical FG. Hopefully this will balance to salt, bitterness and sugar with the umami from the seaweed. Intially we’re thinking of aiming for about 5g/L thin at the end of the boil (5-10 minutes). We’re assuming a 5:1 ratio of the mass between wet and dry seaweed. It’s a guess based on our hops.

Depending on the 20C water test we might ‘dry hop’ the beer to get the BBQ flavour too. We’re going to have to buy more of them as we don’t have enough.

Latest brewing exploits

Three beers to talk about today:

BX21 which we called Photon Rabbit v2. It doesn’t share much heritage with v1 but the idea behind it is the same – a light and hoppy beer for Pen to enjoy. So we started with Magnum Blonde then added some rye malt and torrified wheat. After primary fermentation it was dry hopped with equal amount of Wai-iti, Citra, HBC 431 and Nelson Sauvin. Fermented with US05 it gives a easy to drink, cloudy beer of about 4.5% ABV.

We checked and it doesn’t quite class as a NEIPA because we bittered it during the boil. Not that we care as long as Pen enjoys it and she does. She’s a fan of rye, which adds flavour but also body and head, helped by the torrified wheat.

BX22 is another attempt at making a high taste, low ABV stout. It falls into the Foreign Export Stout category. We’ve called it Disaster Area’s Stunt Ship because “The blackness of it was so extreme that it was almost impossible to tell how close you were standing to it.” to quote Douglas Adams about Hot Black Desiato’s space ship.

This attempt is an evolution – more of the speciality malts, replaced the pale crystal with dark and added raisins during the conditioning.

Still a hot mash, this time for 45 mins rather than 60 and a degree higher. The shorter mash would mean less efficiency and less attenuation. The high temperature would push the efficiency up and lower the attenuation more. A more liquid mash should just increase the efficiency.

The final gravity was a heady 1.040. We’ve had other beers *start* lower than that. However, it’s not particularly sweet and has plenty of taste. Water chemisty has stayed the same, with a 3:1 Chloride to Sulphate ratio. Might try upping that even more next time. The speciality malts currently account for about 25% of the grain bill. Next time I want to take that to over 40%. I’m concerned that there won’t be enough diastatic power left but we’ll give it a go anyway.

I would like to try a nice liquid yeast like Wyeast’s Denny’s 50 or London Ale rather than the dry Lallemand London ESB.

Thirdly, we have a kit beer. We always keep a couple in the cellar just in case Pen starts running out of drinkable beers (with 40+ different beers and over 300 bottles that could be difficult but anyway…) so they need using up before they expire. The oldest was too strong so we went for the Mangrove Jack Lemon Sour Gose.

At first we thought we’d have to delay the brewing because we didn’t have the yeast but eventually figured out that the yeast was hidden in a dry pouch alongside the malt. Then we almost gave up because we didn’t have enough dextrose. We’d mistaken malto-dextrin for dextrose and realised that it probably wasn’t a good substitute. We topped up our dextrose with caster sugar and are hoping for the best.

Stockport Homebrew Competition

We entered two beers, a Mild and a Stout. The Mild was a heavily modified version of the Darkheart Mild. Our first attempt at Darkheart was to clone it as closely as possible and the results came out well (BX17). Pen liked it. However, the second attempt saw changes to the malt bill (added Amber), the yeast (London ESB) and the hops (BX19). It wasn’t as good. A bit thin. So it wasn’t surprising that we finished pretty much last in the Mild category.

The Stout did a bit bitter. Again the basis of this was a recipe from someone whose beer Pen really liked: Aaron. His Imperial Stout really impressed her (and pretty much everyone else) so we tried brewing this, again, as closely as possible (BX18). Not sure how close it was to Aaron’s but both he and Pen liked it. However, Mike didn’t quite get the late addition hops scaled right so Pen though it was too hoppy for the style. No one else at the Home Brew Group agreed though.

So the next step was to scale the recipe for Stockport’s competition. At 10% Aaron’s was much higher than the upper limit. BX18 came out lower because of a higher final volume than intended but was still too high at 7+%. The upper limit for Stockport was 6.5% so we wanted to ensure that the second attempt came in at a sensible strength.

A conversation with Paul from Beatnikz about his excellent stout led us down an interesting path. He mashes at a very high temperature so that they can have lots of malt but keep the strength low. Also he uses water chemistry to shift the taste towards the malty side.

So, that’s what we did and it worked quite well (BX20). We’d aimed for about 6% and got 5.3%. The OG was about right but the FG was even higher than anticipated. We think that there must be even less fermentables in the grain bill than our calculator said. That’s fine though, we don’t mind a lower strength as long as it tastes good. And it does. Pen prefers it to BX18. And this showed. We came third (out of 17) at Stockport!

Mike is now happy – after the poor showing of the Mild and the extract brew he was determined that a milestone should be top three in a category at Stockport and now that goal has been fulfilled. Next milestone ought to be a win in a category there.

Extract Challenge update

The final beer was pretty close to what we’d intended. Mike used his new priming sugar calculator to prime it in a half-filled corny keg. It might still need some time to ferment out though as the reports from drinkers were that it was a bit sweet.

We took it to the home brew group along with everyone else’s attempt. Rich was co-opting people’s APAs (both extract and all grain) into his presentation about Beer Judging. Our was blindly evaluated along with the others and came out last. This was a bit of a surprise because Pen actually quite likes this version. The previous time we did this kit was for the five way split and she refuses to drink those batches.

Extract Challenge March 2019

Rules are simple. 100% malt extract (either from tins or dried malt extract), no specialty malt or partial mash, any hops and any yeast.

Manchester Homebrew Group @mancshomebrew

We started with an extract kit – Simply’s Pale Ale. The kit was cheap and we’d bought it primarily for experimentation. Three kits but only one experiment (five way split with different yeast and carbonation) so two left. Both out of date but nothing else to do with them. Pen didn’t actually like the base beer much so we didn’t much fancy making more beers with them. However, the five way split seems to be improving 18 months later.

It’s not an idea candidate but it’s free and needs using up. We’ve planned to do an American Pale Ale (APA), which fits in nicely with the HBG’s plans:

Any American Pales Ales will help with the introduction to beer judging during the same March meetup.

Manchester Homebrew Group @mancshomebrew

The original kit had a OG of 1.040 for 23L, which includes 1.8kg of extract and 1kg of dextrose. Some maths later and we’ve got about 570 gravity units. Pen doesn’t want a lot more beer (if for no other reason than we’re short on bottles and cellar space) so we’ve opted to make 10L with just the extract giving an OG of 1.057.

Going to use Mangrove Jack M44 West Coast Ale yeast, which should give an FG of 1.011 and an ABV of about 6.2%. We reckon that the bitterness provided by the kit should give the right BUGU ratio. Hopefully the flavours Pen didn’t like from the original were down to the dextrose, not the extract, but we’ll have to see.

The plan is to dry hop the beer shortly after fermentation, leave it for a week and then carbonate in a corny keg (with more hops?). It’ll be the first time Mike’s been able to use his priming sugar calculator that takes into the account head space. 10L of beer in an 19L keg. However, it might add another 0.6% ABV, giving about 6.8%. In the meantime we’ll have to figure out how to bottle from keg.

BX16 Brew Day

This is another beer brewed as part of a Manchester Homebrew Group challenge – the Single Hop Challenge.

After a bit of discussion and some unsuccessful attempts at sourcing experimental hops, the group decided on using Styrian Wolf, a new hop, as the single hop. The rules are pretty simple: you can brew anything you want as long it uses only Styrian Wolf for the hops. i.e. any style, grain bill, adjuncts, yeast and process you want.

Developed by the Slovenian Institute for Hop Research and Brewing, Styrian Wolf is one of the latest Styrian hops on the market. When brewed, expect intense fruity and floral notes. These include flavors of sweet tropical fruits and complex aromas of mango, elderflower and even a hint of violet. — hoplist.com

So what to brew? When asked Pen stated that she wanted a ‘Dark beer’. That rules out quite a lot and it doesn’t make sense to brew something that uses hops just for bittering (i.e. a porter or a stout) or something where other flavours overwhelm the hops (strong Belgian).

Mike had the idea of brewing an Black IPA which should make good use of the hop flavours and aromas, require significant bittering (Styrian Wolf is about 13-14% AA) and definitely meet the ‘Dark beer’ criteria. As an added bonus we could also use some of our more interesting malts. And we can make it a little more special by adding some of the Beekeepers’ Honey we recently obtained. It’ll help up the strength and maybe add a nice note of something else to the end result. Who knows, we’re making this stuff up?

The final design, for 19L @AW consists of Maris Otter, 5-7% each of rye malt, chocolate malt and roast barley, 10% each of honey and Munich malt. 64g bittering Wolf for about an hour and 7-8g/L of dry hops a few days into the ferment. Maybe some more hops in the keg but we’re not at that point yet. Fermented 20L with Nottingham Ale yeast at 18C.

As an aside we drained an extra 4.5L of wort out of the mash by the end of the brew day. Low gravity but still as black as night. Mike plans to boil it down into a malt extract for us in baking and other non-alcoholic projects.

Back to the matter at hand. The brewday, Sunday 7th, went (almost) perfectly. Everything measured out and cleaned the day before. Water sat in the kettle overnight to de-gas. Heating started at about 8am (before we got up!), mashing about 9.30am, sparging before lunch, boiling during lunch (took longer than expected as we need to boil off enough to ensure we could add dissolved honey and not exceed 20L in the fermenter), cooling for an hour and a half, add the honey, activate the yeast, aeriate the wort and finally pitch the yeast. Done for about 3.30pm.

Fermentation took a while to start, about 12 hours longer than normal but we’d intentionally pitched at a lower temperature than normal and kept the heating off in the utility room to try to stress the yeast a bit for a bit more flavour. We figured that Nottingham could handle it easily enough.

And the name of this brew? Dark HASH (Honey And Single Hop).

Tonight (Wednesday) we’ll pitch the dry hops and see how things are going at the weekend.

Lessons learned: Have spares. Mike attempted to re-calibrate the pH meter and it really didn’t want give a consistent reading, even off the buffer solution. With no spare we had to brew without knowing the pH. A new one has been bought and a spare will be ordered shortly. Also ordered a spare water pump for the cooling system. They’re cheap and if ours fails then we can’t cool the wort, which would be awkward. We already have both a kettle element and an induction hob so that covers us for boiling. There’s no other critical active kit fortunately.

‘Will it brew?’ Ingredient

Whilst at Beer Nouveau we picked up our ‘Will it Brew?’ ingredient. Each year the Manchester Homebrew Group issue a challenge; everyone brings in an ingredient (must not be dangerous to humans or yeast) and they’re distributed at random between the group. Obviously you don’t get to brew what you brought. We took potatoes and came away with Grits.

Not knowing what Grits were we had to look them up. Essentially they’re flaked corn, an American thing. Specifically Homity Quick Grits which means the corn was treated and they’re pre-cooked. Corn is very commonly used as an adjunct in brewing, normally to increase the gravity and lower the colour. Thus they’re popular with lager brewers like Millers.

As yet we’re not sure how we’re going to brew with them.

Thursday 5th July – No MBW events

Tonight we are having a night off from beer events. However this doesn’t mean we aren’t doing beer related activities. So we spent the evening cutting out our labels and sticking them onto the home brew bottles we’re entering into the commercial brew on Sunday. After that we cut up even more, this time sheets of flyers for the Manchester Home Brew group, which will be available in Beer Nouveau over the weekend.

We’ve been suggesting business card that the members can hand out informally when they meet beer related people (hop growers, commercial brewers etc.) to promote the group. Many of these people are either interested in home brew or want to be associated with such groups and providing them with a business card is just and easy way to pass on the contact details.

Mike spend a chunk of the week designing a layout and Pen did a bit of printing.